WELCOME TO SAIPTECH——Delivery for clients by building businesses that worth trust

For decades, Saiptech has been a go-getter in mass transfer, phase separation, and reactor internals engineering, leveraging cutting-edge technologies and patented high-performance products. We cater to a diversified client base spanning the petroleum, petrochemical, chemical, and environmental protection sectors, as well as all processing industries engaged in distillation, rectification, absorption & desorption, extraction, and multi-phase separation processes.

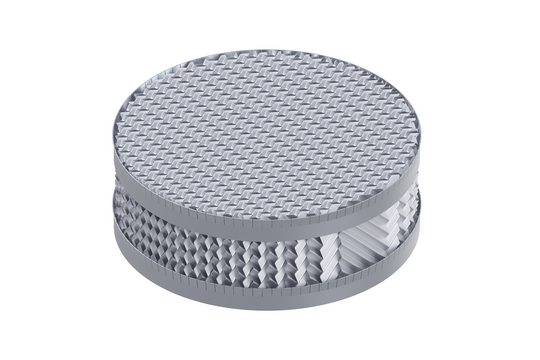

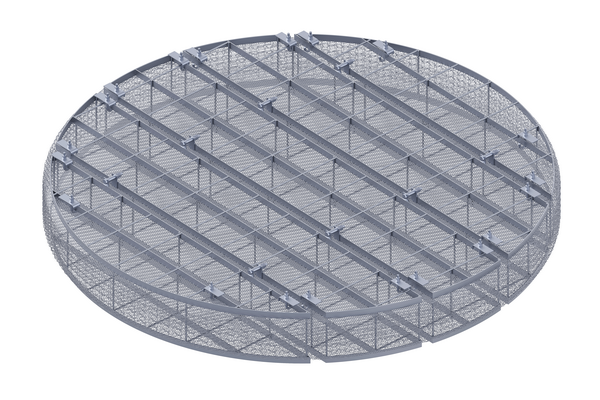

Our unwavering commitment to R&D, coupled with decades of engineering expertise, allows us to deliver fully customized, end-to-end solutions aligned with clients' unique requirements. Our service portfolio includes process simulation and optimization, plant debottlenecking, hydraulic calculation and analysis, on-site troubleshooting, CFD modeling, and dedicated field support. Equipped with a state-of-the-art manufacturing facility, we produce a comprehensive range of premium equipment and components, including distillation trays, column packing and internals, separation internals, and reactor internals. We are committed to delivering high-quality, cost-efficient products and systems with reliable on-time delivery.

At Saiptech, we take immense pride in our team of highly skilled and seasoned professionals. Our workforce consists of technical specialists with decades of hands-on industrial experience in technology development, process and equipment design, manufacturing, system integration, plant design and modification, project management, and process consulting. This diverse cohort of process and mechanical engineers collaborates seamlessly to develop innovative design solutions that consistently surpass client expectations.